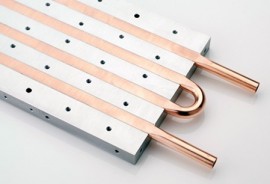

Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Manufacturing Thermo Cool’s custom cold plate options include active and passive cooling solutions. The required thermal performance will dictate the manufacturing method: press-fit copper tubes, epoxy joint, machined-path water blocks, aluminum vacuum-brazed and copper brazed types for various…

Details

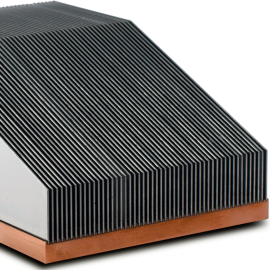

Manufacturing Process Folded fins are created by a progressive stamping method. The fins are then bonded to a base with thermally conductive epoxy, brazing, welding, or similar metallurgical bonds, to create a heat sink. An advantage of folded fin heat sinks is the ability to combine aluminum and copper to tailor the performance of the heat sink to…

Details

Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Materials Aluminum A1060 Aluminum AL1100 Aluminum A6061 Pure Copper CDA 110 Specifications </= 120mm max diameter/width </= 80mm max height 25:1 fin height to minimum gap ratio >/= 0.7 mm fin thickness Applications High performance electronics Multi-chip modules LED cooling Elliptical or round fins Manufacturing Process Cold forging is a manufacturing process…

Details

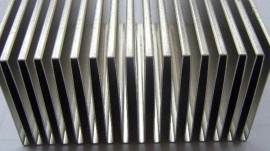

Manufacturing Process Snapped fin (also know as stacked fin or zipper fin) heat sinks are manufactured by stamping sheets of rolled aluminum or copper into a tightly formed array of fins. A progressive tool is used in the stamping process to cut features and then interlock the fins together. Snapped fin heat sinks are most commonly integrated with…

Details

Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Materials Aluminum 6063 Pure Copper CDA 110 Request Design Assistance Specifications 4 foot max profile width <= 10 in profile length 40:1 fin height to minimum gap ratio <= 50 mm maximum fin height 0.2 – 1.0 mm fin thickness Applications Limited…

Details

Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Resources Heat Pipe Store Design Assistance Request For Quote. Specifications 3mm to 16mm standard radius sizes Can be bent and flattened 100mm to 300mm standard lengths Nickle plating Materials Copper Pipe Sintered Wick De-Ionized Water Applications Networking / Telecom Consumer…

Details

Manufacturing Process Die casting is the manufacturing process of injecting liquid molten metal under high pressure into a high precision mold. It is often used to mass produce complex three-dimensional structures with a detailed surface texture. This is done within a single manufacturing step without post treatment. The surface of the die is quickly…

Details

Manufacturing Process Bonded fin heat sinks are manufactured using an assembly process that involves bonding a layer of thin metal fins to a base or substrate. The following is the general process for manufacturing bonded fin heat sinks: Preparation: The base and fins are typically made from aluminum or copper and are carefully cleaned…

Details

Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Zoom Resources Profile Catalog Extrusion Store Design Assistance Request For Quote Applications Extrusions are widely used at almost every level of electronic cooling due to their low tooling cost…

Details