Manufacturing

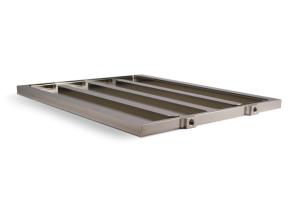

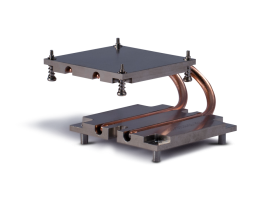

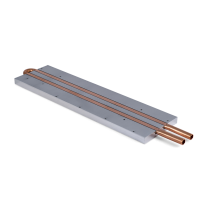

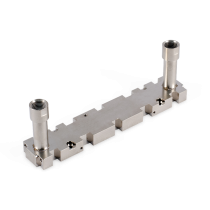

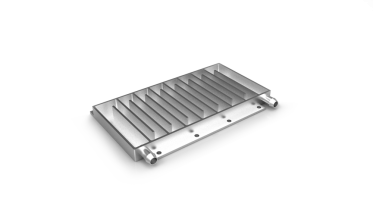

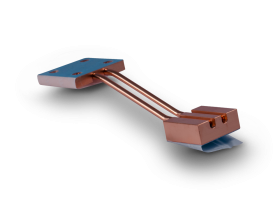

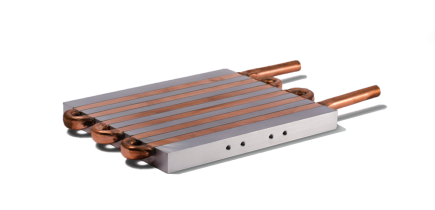

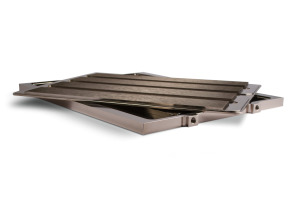

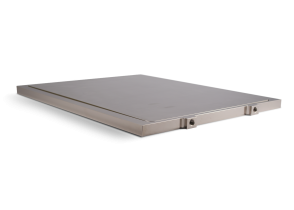

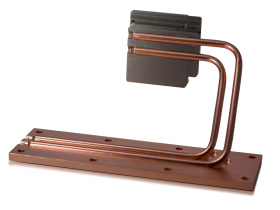

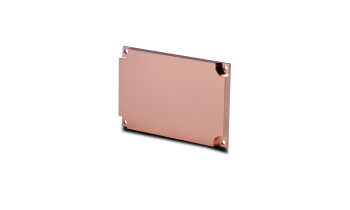

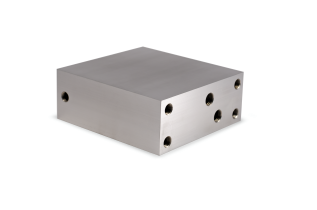

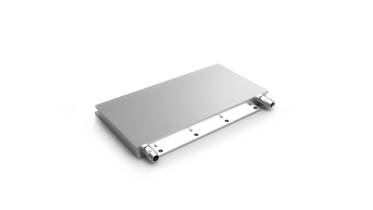

Thermo Cool’s custom cold plate options include active and passive cooling solutions. The required thermal performance will dictate the manufacturing method: press-fit copper tubes, epoxy joint, machined-path water blocks, aluminum vacuum-brazed and copper brazed types for various applications.

Materials

-

Tubing: Copper or Stainless Steel

-

Plate: Extruded Aluminum or Copper

-

Epoxy: Aluminum filled – high thermal conductivity

Specifications

-

Std Copper Tubing: 9.5 mm O.D. x 1.24 mm wall

-

Plate thickness up to 25.4 mm

-

Plate length up to 48 in

-

Plate width up to 10 in

Applications

-

Military / Aerospace

-

Medical equipment

-

Power electronics

-

Lasers / Optics

-

Renewable energy

-

Transportation

Benefits

-

Leak free continuous copper tubing

-

Low cost extruded base

-

High power cooling

-

Maximum surface area

Tooling Cost

Production Cost

Finishing

- CNC machining

- Drilling

- Tapping

- Laser etching

- Polishing

- Fly cutting

- Thermal greases

- Screws

- Springs

- Phase change materials

- Back plates

- Gap filler pads

- PEMS

- Standoffs

- Dielectric pads

- Compounds