Materials

-

Aluminum A1060

-

Aluminum AL1100

-

Aluminum A6061

-

Pure Copper CDA 110

Specifications

-

</= 120mm max diameter/width

-

</= 80mm max height

-

25:1 fin height to minimum gap ratio

-

>/= 0.7 mm fin thickness

Applications

-

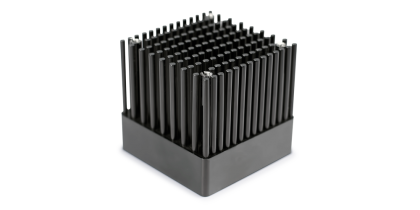

High performance electronics

-

Multi-chip modules

-

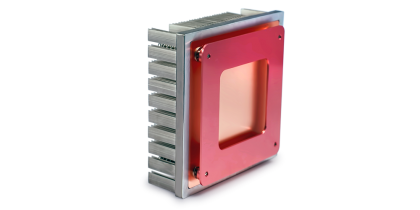

LED cooling

-

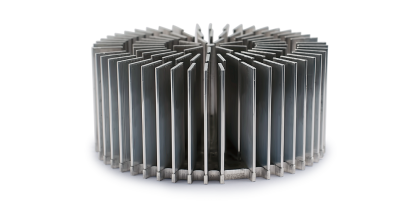

Elliptical or round fins

Manufacturing Process

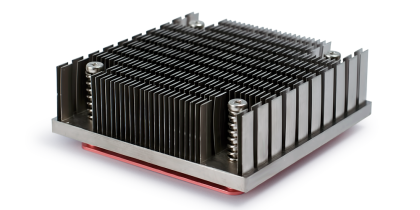

Cold forging is a manufacturing process in which the aluminum or copper heat sink is formed by using localized compressed forces. Fin arrays are formed by forcing raw material into a molding die by a punch. The process ensures that no air bubbles, porosity or any other impurities are trapped within the material and thus produces exceptionally high quality products.

Benefits

-

Improved mechanical strength

-

Better control of tolerance

-

Improved surface finish

-

High production rate

Tooling Cost

Production Cost

Finishing

- CNC machining

- Drilling

- Tapping

- Stamping

- Anodizing

- Screen printing

- Powder coating

- Laser etching

- Polishing

- Embedded fans

- Thermal greases

- Screws

- Springs

- Clips

- Embedded heat pipes

- Phase change materials

- Back plates

- Gap filler pads

- PEMS

- Standoffs

- Dielectric pads

- Compounds