Manufacturing Process

Die casting is the manufacturing process of injecting liquid molten metal under high pressure into a high precision mold. It is often used to mass produce complex three-dimensional structures with a detailed surface texture. This is done within a single manufacturing step without post treatment. The surface of the die is quickly cooled by the mold and the slowly cooling core creates a negative pressure within the cast metal, which inturn makes it more rigid and increases its structural integrity.

Materials

-

Al AA380

-

Al AA384

-

Al AA386

-

Al AA390

-

Magnesium AZ91D

-

Zinc

Specifications

-

4 foot max diameter/width

-

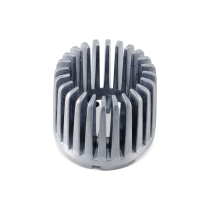

>/= 0.7 mm fin thickness

-

18:1 fin height to minimum gap ratio

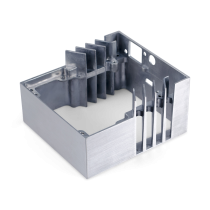

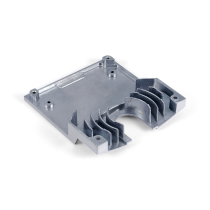

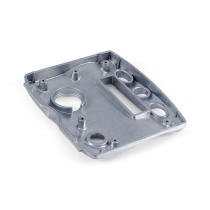

Applications

-

Cases

-

Enclosures

-

Housings

-

LED lighting fixtures

-

Automotive

-

Solar

Benefits

-

Complex shapes

-

Single manufacturing step

-

Durable & rigid

-

Minimal secondary processes

-

Detailed surface

-

High yield rate

Tooling Cost

Production Cost

Finishing

- CNC machining

- Drilling

- Tapping

- Anodizing

- Screen printing

- Powder coating

- Laser etching

- Polishing

- Embedded fans

- Thermal greases

- Screws

- Springs

- Clips

- Embedded heat pipes

- Phase change materials

- Back plates

- Gap filler pads

- PEMS

- Standoffs

- Dielectric pads

- Compounds