Specifications

-

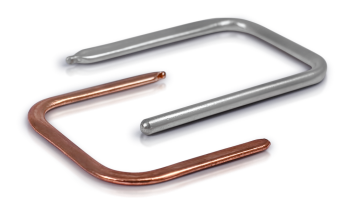

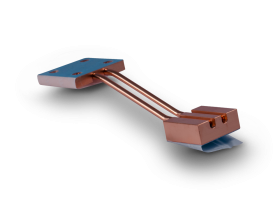

3mm to 16mm standard radius sizes

-

Can be bent and flattened

-

100mm to 300mm standard lengths

-

Nickle plating

Materials

-

Copper Pipe

-

Sintered Wick

-

De-Ionized Water

Applications

-

Networking / Telecom

-

Consumer Electronics

-

TECs

Manufacturing Process

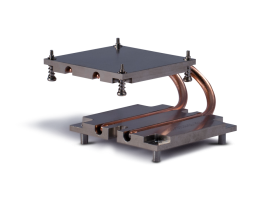

- A typical heat pipe consists of a copper tube in which the inner walls are lined with a wick structure.

- The heat pipe is charged with de-ionized water and then vacuum sealed. This gives the water a lower boiling point.

- When the heat pipe is heated at one end, the working fluid evaporates from liquid to vapor (phase change).

- The vapor travels through the hollow core of the heat pipe to the other end of the heat pipe, where heat energy is being removed by a heat sink or other means. Here, the vapor condenses back to liquid and releases heat at the same time.

- The liquid then travels back to the original end of the heat pipe via the wick by capillary action.

Benefits

-

Very efficient heat conductor

-

Hundreds of times better than solid copper

-

Moves heat / spreads heat

-

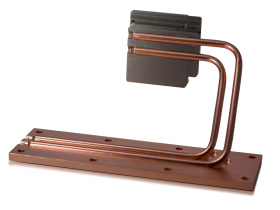

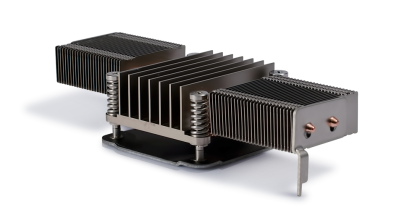

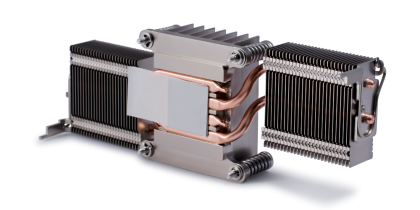

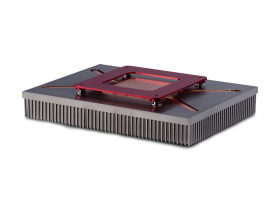

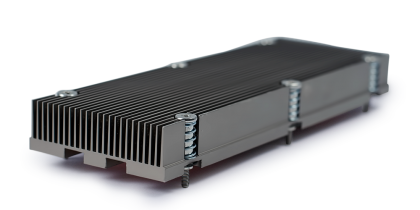

Embed & integrate into heat sinks

Tooling Cost

Production Cost

Finishing

- CNC machining

- Drilling

- Tapping

- Stamping

- Anodizing

- Screen printing

- Powder coating

- Laser etching

- Polishing

- Embedded fans

- Thermal greases

- Screws

- Springs

- Clips

- Embedded heat pipes

- Phase change materials

- Back plates

- Gap filler pads

- PEMS

- Standoffs

- Dielectric pads

- Compounds