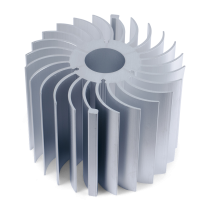

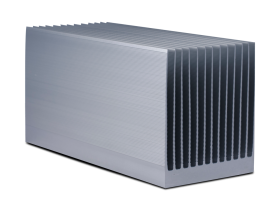

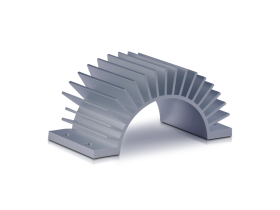

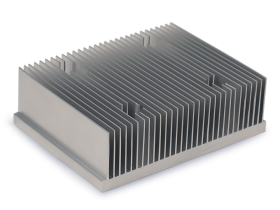

Applications

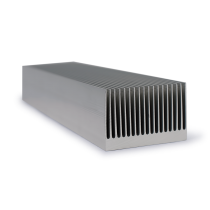

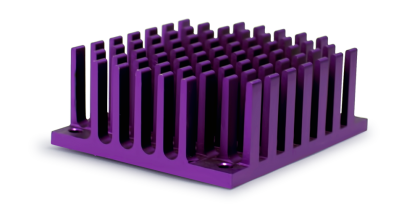

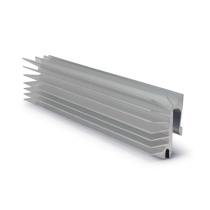

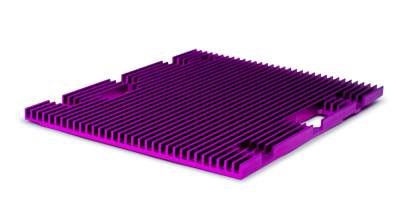

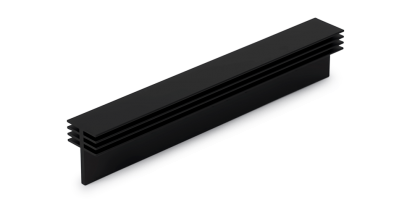

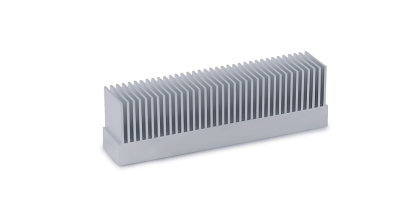

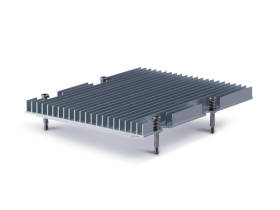

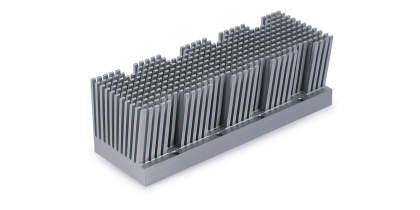

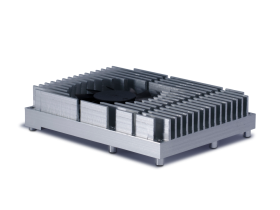

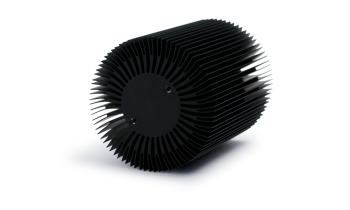

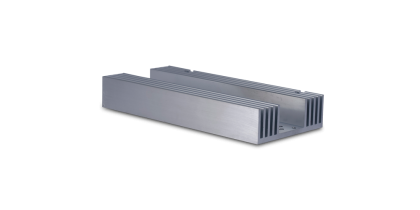

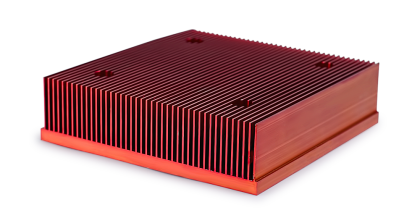

Extrusions are widely used at almost every level of electronic cooling due to their low tooling cost and cost per piece in production quantities combined with effective cooling capabilities.

Depending on the fin configuration, extrusions are suitable for both natural convection and forced air environments.

Manufacturing Process

- A billet of aluminum is heated to temperatures in excess of 900°F.

- Next, the billet is pressed and drawn through a die of the desired cross section by a rod with up to 22 tons of force.

- The extrusion is then manually pulled through the opposite end and cooled.

- In the final stage, the extrusion is cut to the requested length.

- At this point secondary processes are then performed.

Materials

-

Aluminum 6063-T5

-

Aluminum 6061-T6

Specifications

-

24 in (609 mm) max profile width

-

>= 0.5 mm fin thickness

-

22:1 fin height to minimum gap ratio

-

>= 2.5 mm base thickness

Benefits

-

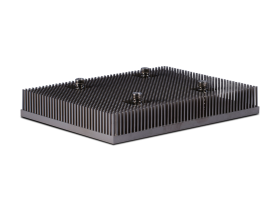

Moderate to high surface area

-

Machinable

-

Available in any length

-

Hundreds of standard profiles

Tooling Cost

Production Cost

Finishing

- CNC Machining

- Drilling

- Tapping

- Stamping

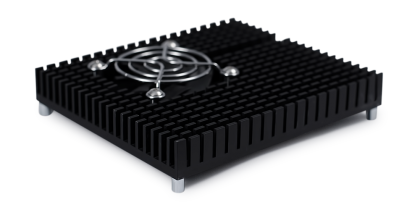

- Anodizing

- Screen Printing

- Powder Coating

- Laser Etching

- Polishing

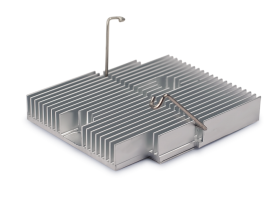

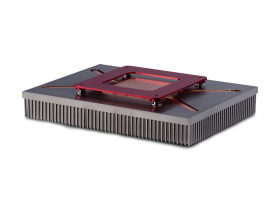

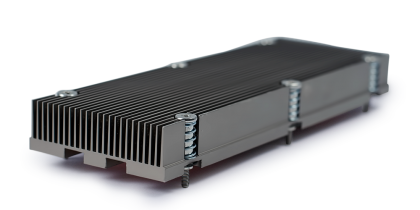

- Fans

- Thermal Grease

- Screws

- Springs

- Clips

- Heat Pipes

- Phase Change Material

- Back Plates

- Gap Filler Pads

- PEMS

- Standoffs

- Dielectric Pads

- Compounds